Rings & Girth Flanges

High-Quality Rings & Girth Flanges by B A Fabricators

Product Description

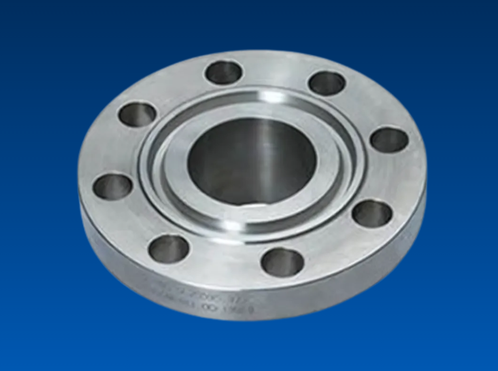

At B A Fabricators and Engineers Private Limited, we specialize in manufacturing precision-engineered rings and girth flanges, essential for structural reinforcements, pressure vessels, storage tanks, and large piping systems. These components are widely used in oil & gas, power generation, chemical processing, and heavy engineering industries.

Our rings and girth flanges are designed for high-strength, leak-proof, and durable connections, ensuring structural integrity and pressure containment. Manufactured using high-quality stainless steel, carbon steel, and alloy steel, they offer excellent resistance to stress, corrosion, and extreme operating conditions.

Customization & Quality Assurance

We offer a range of customization options, including various diameters, thicknesses, pressure ratings, and material grades, tailored to industry standards such as ASME, ANSI, and DIN. Each product undergoes rigorous quality checks and precision machining to ensure optimal performance and longevity.

With our expertise in forging and machining, we deliver robust, high-performance rings and girth flanges designed to meet your industrial requirements. Contact us today for customized solutions!

| CARBON STEEL | ALLOY STEEL | STAINLESS STEEL |

|---|---|---|

| Maximum outside diameter – 2000 mm | Maximum outside diameter – 1700 mm | Maximum outside diameter – 1500 mm |

| Maximum thickness – 350mm | Maximum thickness – 350mm | Maximum thickness – 300mm |

| Maximum weight – 2000 Kg | Maximum weight – 2000 Kg | Maximum weight – 2500 Kg |

Book your appointments

Fill the form to get a call back from us

1

Fill the Form Share your details and requirements with us by filling out the form.

2

Our team will carefully analyze your needs to create a customized solution.

3

One of our experts will connect with you to discuss the best approach and answer any questions

Key Features

- Durable Construction: Made from high-quality steel or aluminum, ensuring resistance to mechanical stress and environmental degradation.

- Weatherproof Design: Sealed to protect against dust, water ingress, and extreme weather conditions.

- Customizable Solutions: Available in various shapes, sizes, and finishes to meet specific client requirements.

- Corrosion Resistance: Coated with advanced anti-corrosion paint for longevity in challenging environments.

- Thermal Management: Designed with cooling mechanisms to handle heat generated during operation.

Applications

- High-voltage substations

- Industrial and commercial power systems

- Renewable energy plants

Advantages

- Enhanced safety for electrical systems

- Reliable performance in extreme conditions

- Easy maintenance and inspection

Why Choose Our Transformer Tanks?

- Custom Engineering: We design tanks tailored to your specific transformer and application requirements.

- Quality Assurance: Our tanks meet or exceed international standards for safety and performance.

- Durable Materials: Built with premium materials and advanced fabrication techniques for long-lasting performance.

- Cost-Effective Solutions: Competitive pricing without compromising on quality.

- Support Services: We offer comprehensive support, from design to installation and maintenance.